Terms | Weight Classes | How To Hitch A Trailer | Hitch Types | Ball Mount Height | Safety Chains | Stability And Sway Control

Hitching

There are various devices used to hitch a trailer to a tow vehicle. Some tow vehicles come already equipped with a towing bumper which negates the need for a receiver as the hitch ball can be secured directly to the bumper. In these cases the bumper will be clearly marked with the maximum tongue weight and trailer weight for safe towing. In other instances, a receiver attachment or hitch must be added to the tow vehicle.

Terms

Hitches and Receivers- Refer to the device attached to the tow vehicle which adapts it to pull a trailer.

Ball Mount- A ball shaped attachment that connects the tow vehicle hitch/receiver and the trailer’s coupler.

Trailer Coupler- Device attached to the trailer tongue that connects to the ball mount.

Tongue- The arm that extends from the front of the trailer that includes the coupler.

Weight Classes

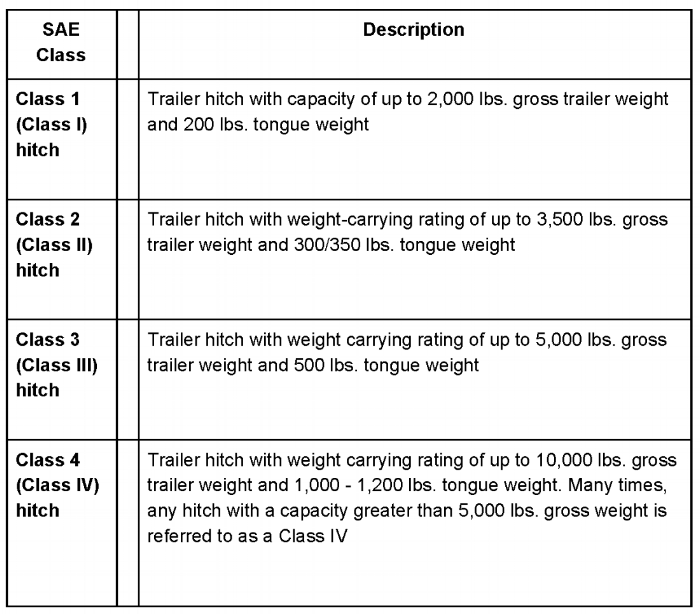

The Society of Automotive Engineers has designated four weight classes for trailer hitches which can be helpful in determining if you have the right hitch for your intended load.

How To Hitch A Trailer

No matter which type of hitch system used, the hitch needs to have a strength rating equal to or greater than the GVWR of your trailer. Your trailer’s maximum capacity is never greater than the lowest rated part in the trailer/towing system. In other words, the weakest link of the trailer should be rated at least as high as the GVWR. You also want to ensure your hitch system is in good working condition and matches the type of tongue on the trailer.

Hitching Using a ball mount system

Ensure each part of the hitch system is in good condition.

Ensure that the hitch/receiver, ball mount, coupler and safety chains or cables (including all attachment components) are sufficient for the loaded capacity of your trailer. Each component must be equal to or greater than the GVWR of the trailer.

Ensure that the ball mount is the correct size such that it matches the coupler for proper fit. Both the ball and the coupler should have the size noted directly on the part.

Ensure the ball mount is at the proper height to ensure your trailer is parallel to the ground when loaded and towed. (See instructions below.)

If not permanently affixed, attach your ball mount according to the manufacturer’s instructions.

Attach the coupler to the ball mount according to the manufacturer’s instructions.

Attach the safety chains from your trailer to your tow vehicle.

The chains should crisscross to form an X beneath the trailer tongue such that it would catch the tongue before making contact with the ground should the trailer disconnect from the tow vehicle.

Each chain shall have a separate attachment point to the tow vehicle and shall be rated for the GVWR of the trailer.

Connect any pin connectors for lighting and, if applicable, brakes.

Ensure your trailer lights are in working order.

hitching using other coupler systems

Gooseneck or 5th Wheel Coupler- Mounted in the bed of a truck, this system is generally used for much heavier trailers.

Fifth wheel style couplers use a king pin similar to that found on the front of tractor semi-trailers. A flat plate with a slot serves as a receiving unit and is mounted in the bed of a pick-up truck, over the rear axle. This type of coupling is designed primarily for highway use.

Similar, but more versatile, is the gooseneck coupler. This is a pipe, or stem, style coupler that connects to a hitch ball, also mounted in the bed of the pick-up, over the rear axle. The gooseneck design takes up less space in the bed of the pick-up and is somewhat more versatile.

Pintle Hitch System- Generally used in heavy duty towing situations, pintle hitches are known for their weight capacities. A basic pintle hitch is a hook and loop system. However, the hitch can be mounted using a pintle hitch ball or a pintle hook around which a lunette ring/eye will sit. Never modify a regular ball mount for use in a pintle hitch application.

A top latch will then close the connection point, using a safety pin to ensure the lock stays in place while towing. Check your connector manufacturer’s owner’s manual to ensure proper hitching.

Hitch Types

While there are a number of hitch types, their function falls into three main categories:

Weight Carrying- Generally used in applications with smaller loads, weight carrying hitches carry all of the tongue weight. Because this weight affects the truck’s handling and braking ability and adds stress to the rear axle, this is not typically the best for heavier load applications.

Weight Distributing- Used in heavy-duty applications, the purpose of this system is to prevent sag due to excessive weight or stress on the rear of the tow vehicle. Rather than merely supporting the trailer tongue weight, weight distributing hitches apply leverage between the towing vehicle and trailer causing the tongue weight to be carried by all axles of the tow vehicle and trailer.

It is important to note that weight distributing hitches do not lend themselves to the proper operation of surge or hydraulic brakes.

Fifth Wheel/Gooseneck- Used in heavier-duty load application, this system located the hitch system over or before the rear axle of the tow vehicle.

A gooseneck hitch looks like a ball mount in the truck bed.

A 5th wheel hitch is a horseshoe shaped attachment.

If you are unsure about which hitch type is best for your trailer and load, contact your dealer or trailer manufacturer.

Ball Mount Height

The trailer will need to ride parallel to the ground when being towed. This is important for stability, proper tire wear, and appropriate stress on the towing combination. As such, the ball mount will need to be raised or lowered as tow vehicles and trailers are often at different heights.

To determine the appropriate rise or drop you will need to measure, on a flat surface, from the ground to the top of the hitch receiver opening and from the ground to the bottom of the coupler on the trailer. The difference between the two provides the necessary rise or drop for a ball mount.

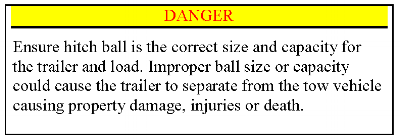

Ensuring the hitch ball is the proper size

Hitch Balls are stamped with their maximum weight capacities

They are purchased based on weight capacities, but also the size of the ball to ensure proper coupler fit, as well as shank width for mounting to the draw bar.

Measuring & Choosing the Correct Ball Mount - U-Haul

Safety Chains

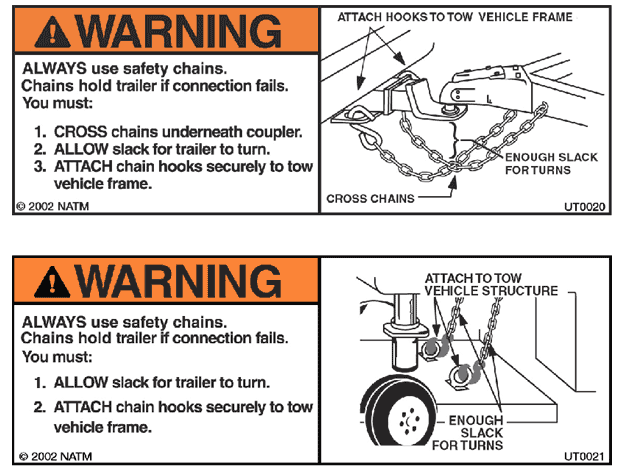

All hitches or tow bumpers must provide a secure location for the attachment of safety chains. Safety chains are your first line of defense if the trailer detaches. State law varies with regard to requiring safety chains. However, their use is recommended.

NATM Safety Chains Warning Label

Crisscross the chains to form an X beneath the trailer tongue so that it would catch the tongue before making contact with the ground should the trailer disconnect from the tow vehicle. Only enough slack to allow turning should exist.

If possible, the chains should be looped back to hook onto themselves

Do not hang an S hook on the opening of the receiver hitch, it might bounce off while driving, but loop it through the opening and connect it to the chain.

Stability and Sway Control

Trailer sway can become dangerous. Factors that contribute to trailer sway are:

Weight of the tow vehicle relative to the trailer.

Hitch load, the tongue weight being too light.

Towing speed is too fast.

Tire inflation.

Design of the trailers, specifically placement of axles.

To mitigate sway:

Ensure you have the proper hitching mechanisms.

Properly load the trailer (i.e. appropriate load distribution).

Follow the instructions in the tow vehicle and trailer owner’s manuals.

Use the driving tips found here.

You may also add a sway control device for additional security related to factors such as sudden maneuvers, wind gusts, and the like. A number of sway control devices are available on the market. You will want to ensure with your trailer dealer that the device is appropriate for your application.